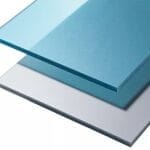

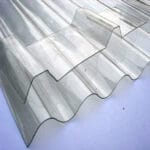

Introduction to Fiberglass sheets Fiberglass (US) or fibreglass (UK) is a common type of fiber-reinforced plastic using glass fiber. The fibers may be randomly arranged, flattened into a sheet (called a chopped strand mat), or woven into a fabric. The plastic matrix may be a thermoset polymer matrix – most often based on epoxy, polyester resin, or vinyl ester – or a thermoplastic.

Fiberglass sheets are used in many types of products. It is used in boats, automobiles, bath tubs, hot tubs, swimming pools, roofing materials, wall facades, cooling towers, tiny houses, transportation trucks…etc.

Fiberglass is a lightweight, extremely strong material that does not rot, corrode, or absorb water. Fiberglass is made by forcing molten glass through a small opening, which is called a bushing. The glass is then drawn into long filaments. These filaments are then laid out in a mat and coated with a plastic resin. The resin is then cured, or hardened, to form the final product.

The main advantage of Fiberglass sheets over other materials is its high strength-to-weight ratio. Fiberglass is also very resistant to heat, chemicals, and ultraviolet (UV) light. Below are some of the main advantages:

Highly Corrosion Resistant

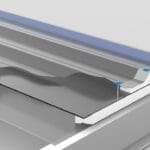

GRP panels can withstand extreme changes in the environment or weather. This is because they are highly corrosion resistant and remain intact for an extended period of time. Any type of chemical hazards, moisture, or dirt has little to no impact on glass reinforced panels when the material used is high quality. This means they do not get cracked or leak or become porous in harsh conditions, which is very much a risk with other alternatives like wood, steel, or aluminum. Its ability to resist corrosion and wear down makes it the most practical solution to any problem you might be facing in terms of roofing.

Very Strong and Durable

GRP sheets have very high strength and durability, which makes them resist any kind of pressure that comes their way. From hailstorms to tornadoes, these panels remain unscratched and easily last you for decades so that you don’t have to make this investment over and over again. Even though they are lightweight, their ability to withstand any kind of weight that would typically break other materials is astonishing.

Inert and Non-Combustible

GRP is an inert and non-conductive material, making it an ideal addition to any industrial site where chemical hazards and combustible gases are constantly present. GRP is highly effective as a thermal and insulator, and is unaffected by electromagnetic or radio waves. If you are looking for a material that will keep you safe and protected while working in a dangerous environment, then GRP is the thing to go for! This is easily the best solution for your industrial property if you are looking to find one!

Frequently asked questions

GRP is basically a glass-reinforced panel that is also called fiberglass or composite panel. It is a sheet that is made of glass fibers combined with different polymers. People also refer to it as “glass-fiber,” so don’t be confused when that word is thrown around. This is a common material used for construction or building purposes that has many applications outside as well as inside. You can use GRP roofing, flooring, wall cladding and so much more!

__

Glass-reinforced plastic or fiberglass is mainly the same thing and is used interchangeably by contractors, so you don’t have to worry about that if you hear the name GRP or FRP instead of fiberglass. Both of these are just a type of Fiber-reinforced polymer, so if the composite material used with resin and plastic is glass, then the material is called glass reinforced plastic.

__

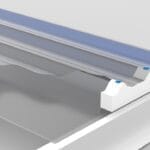

Domer’s Premium and Platinum Shield GRP has a high resistance to Ultraviolet rays, which means it won’t be destroyed when in direct contact with the sunlight. This is because the panels are manufactured by using UV stabilized resins and gel coats or UV reflective co-extruded film that can easily resist ultraviolet radiation and protect the panels from any damage.

__

Even though GRP has a very long life expectancy, it is still a material that you can avail of at affordable prices without worrying about spending too much on the panel. They are a long-term investment, and compared to other GRP roofing alternates like steel, concrete, or anything else; they will always cost you way less as well. With Domer, you will get the best deals on GRP panels!

__

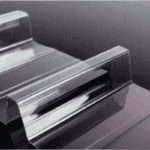

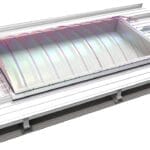

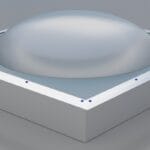

GRP panels can be used to replace many building materials like steel or wood. They are perfect for residential, commercial, and industrial buildings because it is a safe materials that contractors can use to prevent corrosion, weathering, or any other destructive factor. They are also very common because they are very easy to install and build and do not cost much either. You can use it for wall cladding, skylights, fencing, or GRP roofing…

__

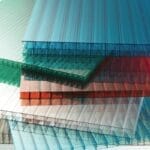

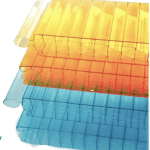

GRP panels can very easily be colored, shaped, or textured as per the customer’s liking. So you can choose what suits the most to your interior or exterior.

__

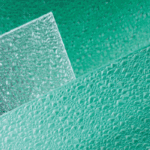

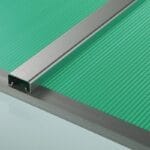

GRP panels can be either flat sheets or textured. If you have specific requirements, you can request textured panels, which can be used for decorative, light diffusing, or anti-slippery purposes, as the texture provides great resistance.

__

GRP panels can go through extreme wear and tear and still survive because they are highly durable and strong. They can easily last you decades, so you won’t have to worry about them weathering off. They are used for construction purposes like cladding and skylights, which makes them the kind of material that can withstand a lot. This also includes poor weather conditions or extreme heat.

__

GRP has a lot of substances that make it flammable and combustible, but they can be customized to turn them into fire-resistant panels. For that, a different type of resin is used, Domer Vivid and Vivaq FR GRP panels are fire and chemical resistant and can be used around places like industries where combustible gases are used on a daily basis. Domer FR GRP panels can achieve Class A of ASTM E84 and Class 0 & 1 of BS476-7

__

Choosing the right supplier for GRP panels is the task you need to consider the most, simply because the right supplier can make it highly customizable for you to achieve the highest specs and best value for money. From different sizes and textures to different colors, mechanical properties, fire classifications, weather-ability and more, you may need to customize your GRP panels according to your requirements. Therefore, your best bet is to go for Domer, who has accumulated years of experience in dealing with glass-reinforced plastic or fiberglass sheets that can complement the interior or exterior of the building. We deal with the best quality materials at the best value you can find in the market. So, choose wisely!

For more information, contact us now!