We have a proven reputation for delivering the highest quality products, with broad and varied sector experience, meeting complex engineering challenges.

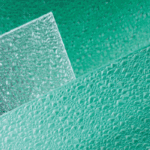

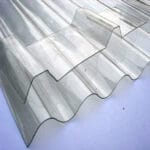

Durapoll NC

Noise Control Polycarbonate

Domer Durapoll NC

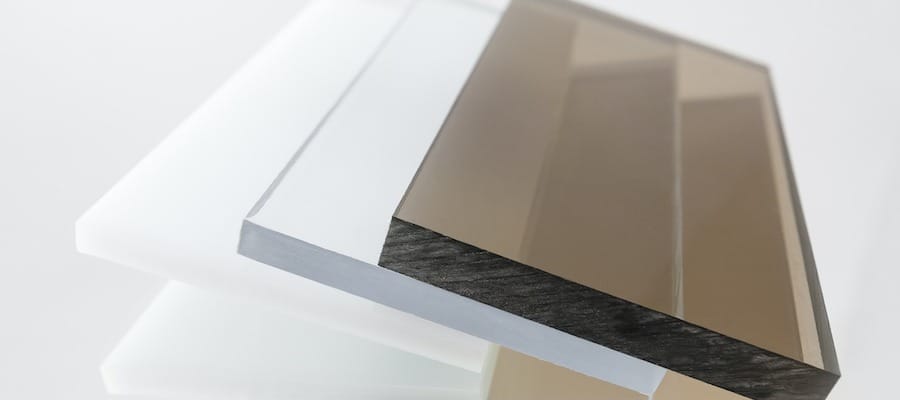

is polycarbonate sheets that reduce noise pollution enormously in railways and highways with heavy traffic, providing healthy and quiet community environments.

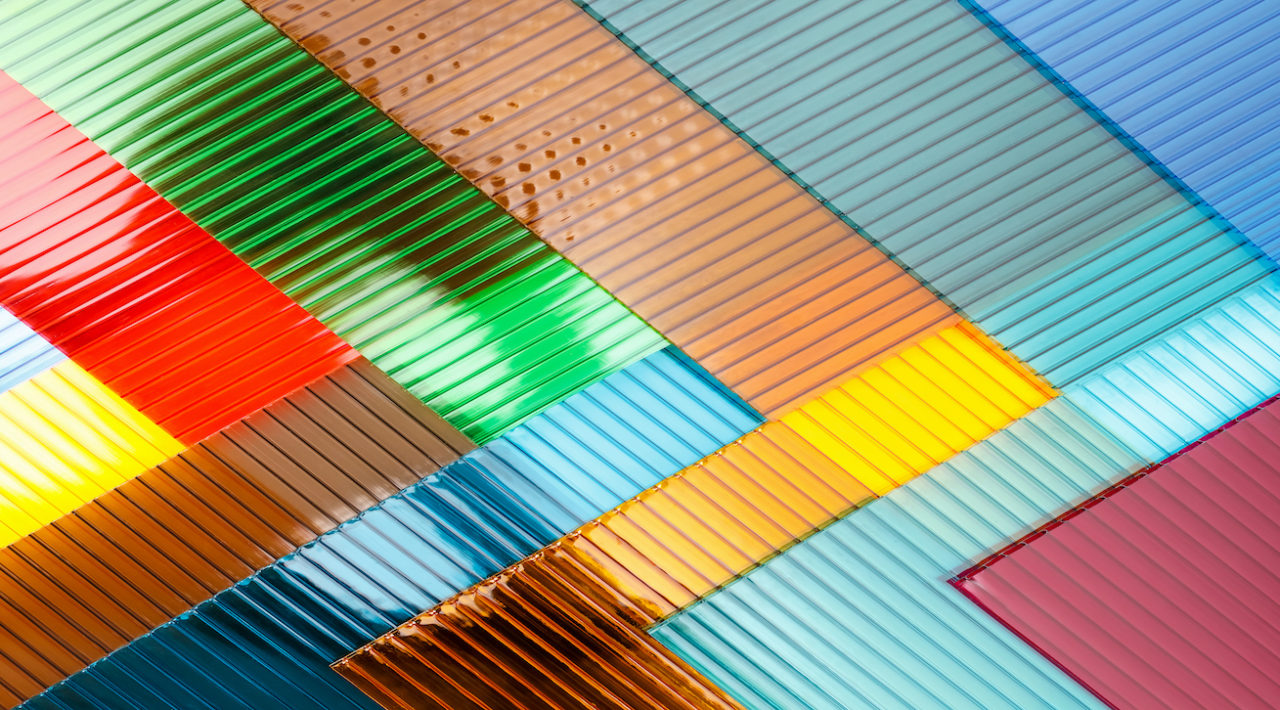

Domer Durapoll polycarbonate noise control sheets are available in a wide range of opaque and translucent colors creating a pleasing aesthetic and friendly environment fitting in any scenario. In addition, they are weather-resistant, virtually unbreakable due to their high impact resistance, meeting the sound technical requirements and demand for road safety.

Applications:

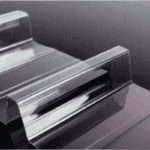

- Highways

- Railways

- Industrial Areas

- Metro Lines

- Race Tracks

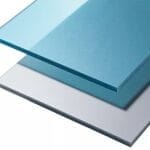

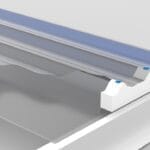

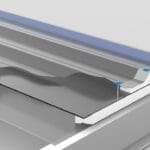

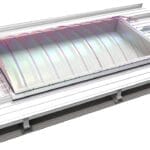

Polycarbonate Sound Reduction

sheets by Domer are lightweight, which allows an easy installation, and can be cold bent or even thermoformed to achieve any designs. Additionally, an abrasion-resistant and anti-graffiti coating can be customized upon request.

Noise pollution created from traffic jams, highways, or railways produces distraction, inconvenience, sleep disturbance, or even chronic hearing damages. Polycarbonate sound reduction barriers help protect neighborhoods, residential areas, and offices from high noise levels providing a pleasant environment and contributing to a healthier life.

Product Benefits:

- Excellent impact resistant

- Lightweight and easy to handle

- Easy to clean

- Excellent acoustical insulation

- Weather-resistant

- Anti-graffiti

| Product Name | Description |

|---|---|

| Domer Durapoll NC | Noise reduction polycarbonate sheets |

| Thickness | Length | Width |

|---|---|---|

| 3.0 - 20 mm | No Limit | ≤2600mm |

*customized sizes are available subject to minimum order quantity

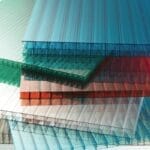

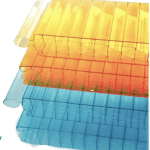

| Type | Color |

|---|---|

| Opaque | white, navy blue, sky blue, dark green, mint green, yellow, light grey, dark grey, red, brick red, orange |

| Translucent | transparent clear, opal, bluewish, greenish, yellowish, greyish, reddish, orange |

*Colors and Finishes can be customized subject to minimum order quantity

| Thickness | Sounds Reduction dB |

|---|---|

| 6 mm | 29 |

| 8 mm | 30 |

| 10 mm | 31 |

| 12 mm | 32 |

| 15 mm | 34 |

| Property | Test Method | Conditions | Units | Value |

|---|---|---|---|---|

| Physical | ||||

| Densitiy | D-792 | g/cm3 | 1.2 | |

| Water Absorption | D-570 | 24 hr. @ 23°C | % | 0.15 |

| Mechanical | ||||

| Tensile Strength at break | D-638 | 10 mm/min | Mpa | 65 |

| Elongation at break | D-638 | 10 mm/min | % | >80 |

| Tensile Modulus of Elasticity | D-638 | 1 mm/min | Mpa | 2300 |

| Flexural Modulus | D-790 | 1.3 mm/min | Mpa | 2350 |

| Rockwell Hardness | D-785 | R scale | 125 |

| Property | Test Method | Conditions | Units | Value |

|---|---|---|---|---|

| Thermal | ||||

| Long Term Service Temperature | °C | |||

| Short Term Service Temperature | °C | |||

| Coefficient of Linear Expansion | D-696 | mm/m°C | 0.065 | |

| Thermal Conductivity | C-177 | W/mK | 0.21 |

| Property | Test Method | Conditions | Units | Value |

|---|---|---|---|---|

| Optical | ||||

| Haze | D-1003 | Clear Sheet | % | <0.5 |

| Light Transmission | D-1003 | Clear Sheet | % | 90% |

| Refractive Index | D-542 | Clear Sheet | 1586 | |

| Yellowness Index | D-1925 | Clear Sheet | <1 |

browse what can be done using our products

Our diverse portfolio represents decades of experience backed by a passion for quality, outstanding client service, and the latest industry technologies.

quality products. inspired design.

unparalleled experience. exemplary service.

Common Questions & Answers

What is the color of polycarbonate sound barrier sheets?

Domer-duplex plating mold laminating with high-precision sheets production line which can produce a broad range of transparent and opaque sound barrier Sheets.

Why polycarbonate is ideal for sound barrier?

In a nutshell, polycarbonate is highly transparent, lightweight, high impact resistant almost 200 times stronger than glass, relatively cost-efficient and recyclable.

Can Domer Durapoll NC sustain rough weather conditions?

Domer Durapoll Noise Control sheets are co-extruded with one or two-sided ultra-violet radiation protection layers which guarantee a long product life against weathering deterioration and discoloration.

Does polycarbonate require any maintenance?

Periodic cleaning of polycarbonate using mild soap detergent, water, and a soft cloth is recommended to prolong the service life. Never use abrasive cleaning agents or glass window cleaners and always test a small area of the sheet first

Goal

We strive to build a better community and make a difference in the world